Mapromec's Anniversary: High Quality and Belief in Our Products Have Sustained the Business for 30 Years

The story of Oy Mapromec Ab, founded in 1994, began with an interest in piston pin manufacturing. Today, Mapromec is one of Europe’s leading piston pin manufacturers with a global customer base and a turnover of over € 15M. Throughout the company’s 30-year journey, certain principles have not been compromised on: export efforts, quality, equality and curiosity.

Mapromec’s journey started in 1994 when Leif Enberg, Caj-Erik Karp, Jan-Erik Kronstrand, Stefan Storgård and Bengt Lundqvist founded the company by purchasing the business operations of Niemi Machines Oy. The founders saw a future particularly in the company's piston pin manufacturing and its development. Niemi Machines' staff was transferred to Mapromec, allowing the development work to continue with skilled personnel and familiar customers.

"Piston pins were, and still are, a critical engine component requiring the kind of expertise that is not commonly found. We believed Niemi's piston pin manufacturing had a future and huge development potential," Enberg explains.

As operations developed and exports were initiated, Mapromec’s customer base grew. Alongside piston pins, the company’s product range expanded to include lifting rollers, bearing parts and side and cylinder head covers. Mapromec was an early forerunner in production automation, acquiring its first robotic cell in 1998. Today, there are 17 in total.

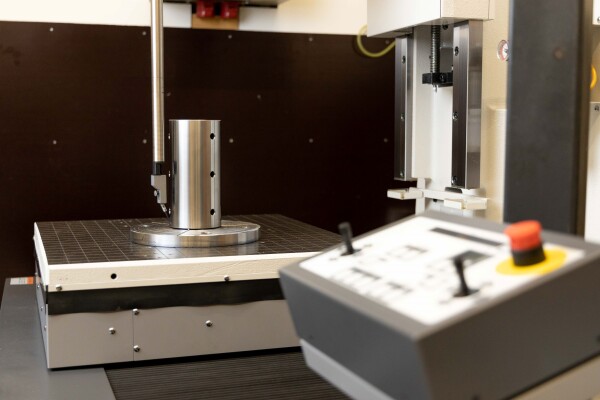

Mapromec's quality performance, another characteristic feature of the company, was a strength even in the 90s. Mapromec already used ultrasonic inspection equipment and Magnaflux® particle inspection, and had already been approved for ISO 14001 and 9001 quality and environmental certificates. Especially with the environmental certificate, Mapromec was a forerunner within the industrial field. Mapromec ensures high quality through various methods and solid experience at every production stage, from material procurement to documentation. In addition to ultrasonic and particle inspection, low staff turnover has also been a crucial factor for quality throughout the company's existence.

"Quality, as well our loyal, trained staff, have been the cornerstones of our operations from the start. A testament to our quality performance is our strong supplier role in the nuclear power industry – in environments where quality criteria are extremely high."

After challenges, a new day dawns

Throughout decades of operation, Mapromec has also encountered periods of heightened turbulence. One notable event occurred in 2012 when a large-scale fire struck the company, garnering media attention. Thanks to a dedicated staff and smooth cooperation with the insurance company, all customer deliveries were completed despite the damage.

Another challenging period came during the global pandemic in 2020. Demand plummeted and operational conditions changed significantly. To remedy the situation, changes were initiated, focusing business on the most essential functions. Chairman Leif Enberg steered the company through the challenges, and eventually, business development and investments could continue.

"Because of the commitment and patience of our staff and customers, we have been able to turn the tide in challenging situations and continue moving forward even stronger. After challenges, a new day dawns."

Strong and Proactive Communication and Meeting Requirements are the Basis for Customer Collaboration

As of 2022, Mapromec has been led by CEO Tapio Kaunismäki. For Kaunismäki, the focus areas now and in the future are clear. They include maintaining and developing the level of automation and processes, quality assurance, staff competence and well-being, as well as close, partner-level customer cooperation. Mapromec invests in regular communication and aims to work directly with customers, leading to mutual partnerships. According to Kaunismäki, trust is the core of cooperation: confidentiality agreements are taken seriously, customer information is secure in all situations and no empty promises are made.

"Through strong and proactive communication, we are constantly aware of our customer's operations, projects and needs. This is a key factor for a successful partnership."

Another essential part of collaboration is meeting customer requirements, in which environmental impact considerations are becoming increasingly significant. Mapromec strives to minimize operational environmental impacts by implementing concrete measures, such as transitioning to carbon-neutral district heating and reducing the use of plastic. Mapromec is currently working to meet the requirements of the ISO 14064-1 certificate in the future.

Employees are a Company’s Strength

According to both Enberg and Kaunismäki, one key factor has enabled Mapromec’s 30-year journey: the staff. Skilled personnel have been the company’s strength from its founding to the present. Mapromec works for staff well-being by providing versatile career paths, competitive benefits and salaries as well as comprehensive occupational health care. Mapromec offers continuous training and invests in occupational safety. Recently, Mapromec has also renovated premises to increase staff’s comfort. Workplace diversity is important to Mapromec.

"In addition to open-mindedness, our most important staff value is humanity and caring for each other and our well-being. We are interested in and monitor this through regular staff surveys."

Curiosity and Belief in Our Products Lead to a Bright Future

In the future, Mapromec aims to support its current customer base with new industries. Other goals include maintaining a good profitability level, promoting customer collaboration and staff well-being as well as continuing to implement the investment and development plans. The latest investment is nearing completion: in the summer, Mapromec’s machinery will be complemented by a new Okuma grinding machine, enabling the grinding of even larger components. Grinding is one of the most crucial production stages for component quality, which makes the investment significant.

"The new machine, together with our other production and quality assurance processes and the expertise developed over decades, forms a unique combination. The investment increases our capability and further strengthens our foothold in the nuclear power industry."

Continuing business operations for 30 years, even amid challenges, is not a given. When reflecting on the past decades, Enberg and Kaunismäki emphasize listening to customers and responding to their needs with development and investments, alongside the dedication of their staff, as key success factors.

"From the beginning, we have focused on what we do best and that is what we will continue doing. Ultimately, it’s about believing in the high quality of our products that meet our customers' requirements. As we continue to develop the foundational pillars that have guided us from the start and remain curious and proactive, we see a bright future for Mapromec as a leading industry player."

Mapromec celebrates its 30th anniversary on June 14th together with the entire staff. The celebration day is a milestone for long-term business operations and a tribute to the dedicated staff.